Resourcing Resilience Across Africa

Bold innovations in funding health systems

Opalia is an Impact Entrepreneur nominee for the 2025 Earthshot Prize.

Walk into any grocery store or coffee shop, and you are likely to be presented with an endless variety of dairy and dairy-free options. From whole milk and skim milk for the lactose tolerant crowd, to oat milk and almond milk for fans of the nut-based alternatives, there is a “milk” out there for everyone.

But thanks to recent advancements in technology, there is a new milk alternative that could soon find its way into many of our favorite dairy products such as butter, cheese, chocolate and ice cream. Enter Opalia, maker of a new cell-based milk that combines the nutritional benefits and taste of real milk with the environmental benefits of a product that doesn’t rely on animals.

In this Q&A, I talk to Jennifer Côté, founder of Montreal-based Opalia, about her entrepreneurial journey and why the market is ready for a new type of milk.

Jennifer Côté, founder of Opalia

Q: What inspired you to explore cell-based milk?

Jennifer: During the pandemic my co-founder, Lucas House, and I were looking for a big project that resonated with our values. It was clear to us that society was going to have a hard time feeding people and that there needed to be more innovation in how we produce food. I was also vegan at the time and not satisfied with the existing plant-based options. We were seeing a lot of media attention around cell-based meats and realized there was an opportunity to take a similar approach with cell-based dairy. After all, people can give up meat fairly easily, but when it comes to dairy products like butter or cheese it can be much harder.

We knew we had something and started building a team in 2021 to develop a proof of concept. I had a business background so I took the lead there, while Lucas had more of a science background so he became CTO.

Q: How does the process work?

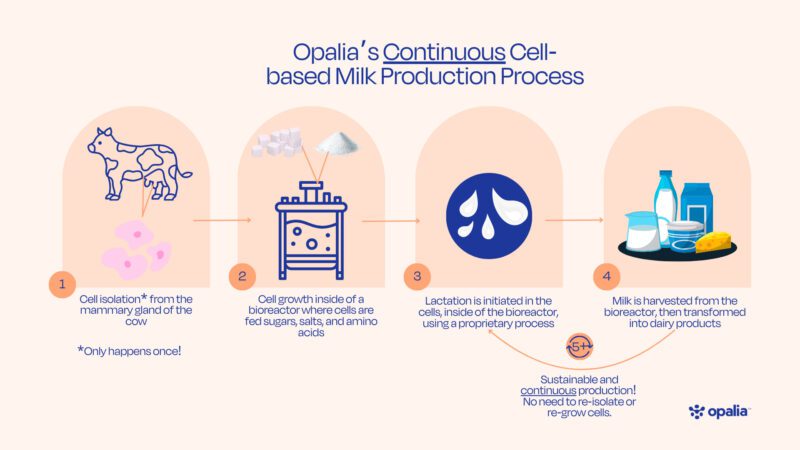

Jennifer: Opalia’s process consists of harvesting a single sample of mammary cells from a lactating cow, growing them by administering minerals, sugars, salts and amino acids, making them lactate using our proprietary method, and harvesting the milk produced continuously without having to subsequently harvest cow cells or re-grow them. This is a continuous process from the moment the cells have reached the desired number. Since the cells divide every 24 hours, the Opalia team is able to reach the desired quantity after one to three weeks of growth. This number of cells is then maintained and lactation can begin for a theoretically unlimited duration.

We were seeing a lot of media attention around cell-based meats and realized there was an opportunity to take a similar approach with cell-based dairy.

So, because we control each step in the chemical system, we can make all types of different products, whether that’s lactose-free milk or milk with high casein and low whey protein. For instance, with lactose-free milk, it actually makes more sense to remove the lactose before the chemical process rather than separating it from the finished product like what happens with other lactose-free milks. Right now, we’re focused on making milk for B2B applications and offering customers a customized product depending on their needs.

Q: What lessons did you learn from the successes and failures of cell-based meat?

Jennifer: With cell-based meat, the end product is so much different from the real thing. Recreating meat is much more complicated and requires a lot of expensive technology, especially since you have to regrow the cell every time you want more meat. In contrast, Opalia’s process is fully continuous, so you only have to grow the cells one time and then can make milk for months. The end product is also much less complex because it’s just a fluid, which means you don’t need to worry about the texture, the mouthfeel or the structure. This also makes cell-based milk much more accessible and easier to scale than cell-based meat.

Opalia Process Infographic

The market dynamics between meat and milk are also quite different. Meat is something that is seen as a luxury good in some parts of the world, whereas dairy is a part of people’s everyday lives. We’re also seeing increased demand for milk in Asia, which could offer exciting growth opportunities.

Obviously, there was a lot of investor interest in cell-based meat. We’re still in the early days for cell-based dairy but it’s starting to take off.

Q: Which questions do you get the most often from prospective customers?

Jennifer: The most common question is probably, “Does it taste like milk?” And yes, it does! We also sometimes get questions about functionality, in terms of a product that doesn’t require different cooking or prep methods. We’ve found that customers want a product that meets them where they are, and that’s something that other plant-based alternatives have struggled with.

Opalia Team

Q: What are the environmental benefits of your approach?

Jennifer: So obviously there’s been an increased awareness and urgency around addressing greenhouse gas emissions. And there have been a lot of studies about the benefits of animal-free dairy products. For instance, we believe that Opalia’s technology has the potential to produce up to 95% less greenhouse gases, use up to 90% less land, and suck up 97% less water than existing dairy production methods. By eliminating the cow from the milk-making process, we also eliminate methane production and significantly reduce CO2 production and land use by not relying on acres of soybean and corn to feed and raise livestock.

Another advantage to using bioreactors instead of animals is that the technology can be deployed in all kinds of climates. Localized milk production only requires access to electricity, water and a supply chain for cell food. Eventually we see Opalia’s production process being co-located next to transportation facilities, further reducing GHG emissions from every time the milk is moved.

I think it’s also important to think about public health and protecting against another pandemic. This is a big concern with the continued rise in population, which means the demand for protein will increase and so will the number of animals. More animals leads to a higher risk of contamination, especially as more and more animals are put into smaller locations, which then leads to increased antibiotic use, which is also extremely concerning for global health due to the growing risk of antimicrobial resistance.

We’ve seen lots of viruses emerge from food production – avian flu (affecting chickens and other livestock, including cows), swine flu (affecting pigs), and others — that can sometimes make the jump to humans. Fortunately, our technology can eliminate the risk of disease because the production process is all sterile and fully traceable, so we don’t have to worry about the risk of bacterial contamination.

Opalia’s technology has the potential to produce up to 95% less greenhouse gases, use up to 90% less land, and suck up 97% less water than existing dairy production methods.

Q: What are your future plans for the business?

Jennifer: Our focus right now is on scaling. We have been able to validate the technology at the lab scale, and now we want to get fully commercialized and get more customer traction. The goal would be for a public rollout sometime in 2028 and 2029, but we plan to have public tastings before that. We expect to start the regulatory approval process early next year, as well as R&D pilot projects with our existing customers. The rollout will likely be in North America first and then we can look at other countries.

We’re also still fundraising and actively looking for investors or other partners to support us on this journey. It’s been really surprising to see the level of interest in Opalia — not just among big dairy companies but also family and friends. That’s how we know we’re building something that fits a real market need.

Q: What’s your ultimate goal with Opalia?

Jennifer: I want to see Opalia become a proven supplier for food and beverage companies. Longer term, I would like Opalia to make a dent in the carbon footprint of the dairy industry and the food/beverage industry in general. The end goal would be to not use animals for subsistence and instead use technology to make the food we need.

Related Content

Comments

Deep Dives

RECENT

Editor's Picks

Webinars

Featuring

Elizabeth Boggs Davidsen

CEO of GSG Impact

May 8 - 12:00 PM EST

News & Events

Subscribe to our newsletter to receive updates about new Magazine content and upcoming webinars, deep dives, and events.

Become a Premium Member to access the full library of webinars and deep dives, exclusive membership portal, member directory, message board, and curated live chats.

At Impact Entrepreneur, we champion fearless, independent journalism and education, spotlighting the inspiring changemakers building the Impact Economy. Diversity, equity, sustainability, and democracy face unprecedented threats from misinformation, powerful interests, and systemic inequities.

We believe a sustainable and equitable future is possible—but we can't achieve it without your help. Our independent voice depends entirely on support from changemakers like you.

Please step up today. Your donation—no matter the size—ensures we continue delivering impactful journalism and education that push boundaries and hold power accountable.

Join us in protecting what truly matters. It only takes a minute to make a real difference.

0 Comments