The Algorithmic Classroom

South Korea’s ambitious experiment with AI in classrooms holds lessons for the world

A profile of Entropy Resins

In the world of action sports there are a handful of entrepreneurs working to solve the environmental issues that have run in parallel with the industry’s innovations. Two brothers from California who grew up surfing, skating, and snowboarding have taken the first step to make a little-known, yet widely used base-material — that is essential to some of the most popular action sports equipment — more environmentally friendly.

The majority of innovations made in action sports equipment over the last 60 years can be mapped back to one concept and a handful of new materials that enabled entrepreneurs to apply it. The underlying principle for making equipment like skateboards, surfboards, and snowboards perform better than their predecessors is to make them both stronger and lighter. Before the proliferation of petroleum-based materials like Styrofoam, fiberglass, and epoxy resins, action sports entrepreneurs were limited to materials like wood and metal which meant they had to choose between making their boards stronger or lighter. After these petroleum-based materials became available, entrepreneurs in every sector of action sports integrated them into their products, revolutionizing their respective industries.

To understand how transformative these materials were to sports – especially if you aren’t familiar with action sports – let’s take a look at a similar innovation in a more popular sport. Consider a tennis match between two elite players where one is playing with a wooden tennis racket from the 60’s and the other with a modern composite racket of the 80’s or later. The modern rackets are stronger, lighter, and more flexible providing for better handling and much stronger strikes to the tennis ball. It’s an unfair competition. The same is true when you look at the performance of action sports equipment, and while the stakes aren’t as high for a hobbyist, everyone wants to have the best possible gear when skating, snowboarding, or surfing.

Petroleum-sourced products have a high carbon footprint to produce, can pose a health hazard during production and disposal, and we currently have very few solutions for recycling or reusing them.

The last generation of entrepreneurs solved the strong vs light tradeoff conundrum. Now we have the best of both worlds; except there is the inconvenient problem that the source materials enabling this performance poses an environmental dilemma. Petroleum-sourced products are unsustainable. They have a high carbon footprint to produce, can pose a health hazard during production and disposal, and we currently have very few solutions for recycling or reusing them. As you may have expected, where there is a problem there is an entrepreneur working to solve it, and this where the Banatao brothers come in.

The Banatao brothers of Entropy Resins have developed a bio-based epoxy resin that helps reduce the environmental impact of the material without sacrificing performance. Epoxy resin is one of the core building blocks of adding strength and lightness to performance equipment. It’s used as an adhesive, sealant, composite, and coating (just to list a few). In surfboards for example, it’s used to create a strong, light, and waterproof shell around a light and buoyant foam core. Epoxy’s versatility and performance are unrivaled, which is why it’s the industry standard. But the impact of epoxy resins radiates far beyond just action sports.

Epoxy resins are a foundational material found in everyday products ranging from paints to electronics to vehicle components. As with other materials that fall under the umbrella of plastics, epoxies have infiltrated just about every aspect of our lives. That means the total carbon footprint stemming from this one source material is massive. If we can find a more sustainable alternative with the same properties, it has the potential to reduce the footprint of thousands of products. That’s why the Banatao brothers set out to create a biobased epoxy resin.

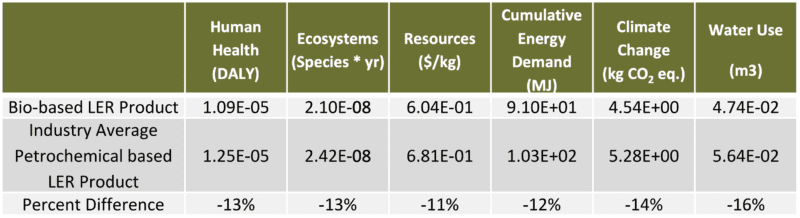

In their effort to reduce the environmental impact of their resins as much as possible, Entropy Resins built lifecycle analysis (LCA) models for petroleum-based resins and their biobased resins, then compared the two. Their LCA found their biobased resin to be less impactful across all categories by about 11 – 16%. They’ve made these improvements by incorporating green chemistry, biobased and rapidly renewable raw materials, and efficient manufacturing.

Bio-based vs. Petroleum-based Resins; (Source: Entropy Resins LCA)

The Banatao brothers, Desi and Rey, one an engineer and the other a chemist, started working on their bio-based resins in 2008. By 2018 they had built a company with global supply chains and customers around the world. Now, their resins are used by mainstream brands like Burton snowboards and Stretch surfboards, as well as artists and woodworkers who seek the qualities of epoxy resins with a lower environmental impact. Entropy Resins was able to make this reduction by replacing a portion of their resin’s petroleum-sourced polymers with the same polymers from pine trees and vegetable oils.

They sell a range of resins, each modified for various use cases. All of their products are certified biobased under the USDA. This certification requires a minimum of 25% of the product to be sourced from biobased materials. The biobased content of Entropy Resins products varies, but most are 30% biobased.

Entropy Resins was able to make this reduction by replacing a portion of their resin’s petroleum-sourced polymers with the same polymers from pine trees and vegetable oils.

Entropy Resins continue to innovate biobased materials to make improvements to the environmental footprint and performance of their resins. They recently launched another project with a goal of addressing end-of-life issues of epoxy by making them easier to recycle. They are expanding their market reach to get their biobased resins used more frequently with the help of their parent company Gougeon. As the cofounder, Desi Banatao said, “We joke that we are trying to save the world one snowboard at a time but you have to start somewhere right?”

Related Content

Comments

Deep Dives

Featuring

Clarisse Awamengwi

IE Correspondent

July 17 - 12:00 PM EST

Featuring

Russell McLeod

July 24 - 12:00 PM EST

RECENT

Editor's Picks

Webinars

News & Events

Subscribe to our newsletter to receive updates about new Magazine content and upcoming webinars, deep dives, and events.

Become a Premium Member to access the full library of webinars and deep dives, exclusive membership portal, member directory, message board, and curated live chats.

At Impact Entrepreneur, we champion fearless, independent journalism and education, spotlighting the inspiring changemakers building the Impact Economy. Diversity, equity, sustainability, and democracy face unprecedented threats from misinformation, powerful interests, and systemic inequities.

We believe a sustainable and equitable future is possible—but we can't achieve it without your help. Our independent voice depends entirely on support from changemakers like you.

Please step up today. Your donation—no matter the size—ensures we continue delivering impactful journalism and education that push boundaries and hold power accountable.

Join us in protecting what truly matters. It only takes a minute to make a real difference.

0 Comments