Rethinking Copyright in the Age of Generative AI

Striking a balance between incentives and innovation

Half of the top ten offenders for releasing plastic waste into the ocean are countries in Southeast Asia. Another three — China, India, and Bangladesh — are just outside of this region. Part of the problem is their proximity to the ocean, but equally important is their lack of infrastructure to process plastic waste. As plastic consumption in countries like Vietnam and Indonesia grows faster than processing can keep up, plastic waste continues to increase. But a few impact entrepreneurs who see massive potential for reformation are working to help us change course.

With the 7th fastest growing middle class in the world and 70% of its population living in coastal and delta areas, Vietnam’s contribution to plastic in our oceans is growing faster than most. The key challenges for countries like Vietnam are: 1) having the systems to collect plastic waste, 2) sort them properly, and 3) process them properly.

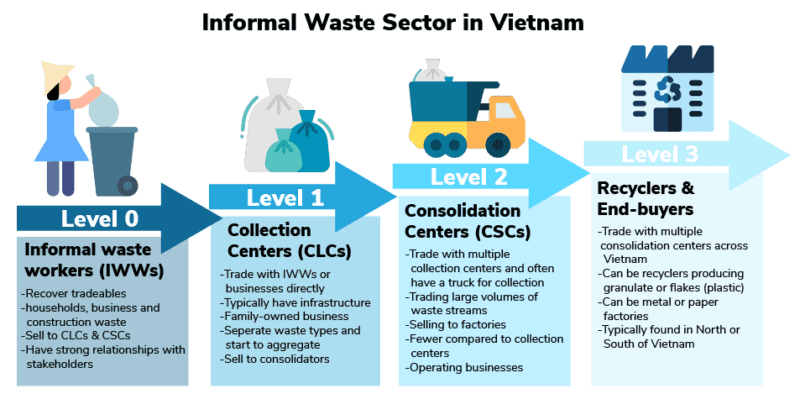

Today, most recycling and reuse of waste in Vietnam is collected and sorted via the “informal sector”, which refers to a vast, unorganized network of pickers, collection points, and consolidators who then sell to recycling factories. This micro economy has developed as a way to derive value from waste, but is still highly inefficient and unequal. Current collection is mainly limited to metals and cardboard.

Plastic is one of the least-recycled materials, and, as such, the biggest opportunity to recapture lost value. It’s estimated that 2.62 million tonnes of plastic are disposed of each year in Vietnam and only about a third are recycled. This translates to over $2 billion of potential plastic material value loss. To put this in perspective, Vietnam’s total GDP in 2021 was $362 billion.

While pickers — consisting primarily of women over the age of 40 working via bicycle — are able to make a living in this line of work, they are subject to what aggregators are willing to pay and, thus, have little to no security. As one such Vietnamese woman, Ms. Xuan Hoi An, who now works at a ReForm Plastic facility said, “Before working at ReForm Plastic, my income was uncertain, and I worked long hours. When combined with the pressure to provide for my family, those difficulties are not easy for a middle-aged woman like me”.

This informal system poses three fundamental problems. The first problem is that, on top of the physical demand and day-to-day uncertainty, informal waste workers collecting and sorting rarely receive fair compensation for their daily haul. The second, economic problem is a limitation of growth; being able to only reclaim a tiny portion of waste that is otherwise valuable if properly recycled limits the size of the economy itself. And, of course, there is the third, environmental problem — as the externalities from this inefficient process add up, our environment foots the largest bill.

An ideal solution to this trifecta helps transition the existing microeconomy into a more efficient and sustainable system, delivering a win-win-win for the people, planet, and economy. This is an opportunity the founders of ReForm Plastic saw when they analyzed the informal waste sector in Vietnam, before developing their full value chain solution.

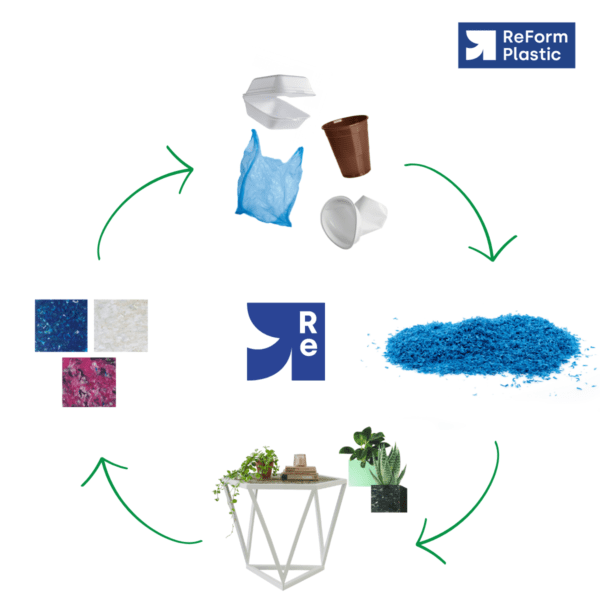

ReForm Plastic introduces new technology into existing operations to unlock the latent value of non-tradeable, low-value plastic. At the core, ReForm Plastic technology sorts and repurposes various types of plastics into commodity board products. The input is everything from single-use items, wrappers, multilayers, flexibles, and styrofoam. The output is plastic-molded products with various applications, such as tiles for construction, tables or chairs, cabinets, waste bins, playgrounds, and even rock-climbing walls. The approach is fully circular; ReForm Plastic can take back old products and re-process them again to give them a new life. ReForm Plastic provides additional income streams to local communities and informal workers by enabling them to collect and trade new materials. ReForm Plastic processing and remolding technology is franchised to existing processing facilities, enabling those facilities to expand their capabilities and increase revenues. This economic incentive encourages existing facilities to be part of an environmental solution and the franchise model is a faster way of scaling processing capabilities. All of this means more plastic waste is diverted from landfills, incinerators, and the environment.

ReForm Plastic introduces new technology into existing operations to unlock the latent value of non-tradeable, low-value plastic. At the core, ReForm Plastic technology sorts and repurposes various types of plastics into commodity board products. The input is everything from single-use items, wrappers, multilayers, flexibles, and styrofoam. The output is plastic-molded products with various applications, such as tiles for construction, tables or chairs, cabinets, waste bins, playgrounds, and even rock-climbing walls. The approach is fully circular; ReForm Plastic can take back old products and re-process them again to give them a new life. ReForm Plastic provides additional income streams to local communities and informal workers by enabling them to collect and trade new materials. ReForm Plastic processing and remolding technology is franchised to existing processing facilities, enabling those facilities to expand their capabilities and increase revenues. This economic incentive encourages existing facilities to be part of an environmental solution and the franchise model is a faster way of scaling processing capabilities. All of this means more plastic waste is diverted from landfills, incinerators, and the environment.

ReForm Plastic has 6 facilities operating and 4 more being installed. The first, standalone facility was built to prove the model and is still in operation. The other facilities are franchises who have expanded existing operations to be able to process non-recyclable plastics into products. ReForm Plastic aims to accelerate current growth and go from 10 facilities to 100 by 2030, in addition to adding complementary technologies that address the entire range of municipal solid waste.

Beyond expanding capacity via more facilities and technologies, ReForm Plastic seeks to further help the informal waste sector by launching a resource hub and support network. The new hub will provide information, help coordinate events and training, and make it easier for informal waste workers to connect with businesses for opportunities. Coordination and information exchange is another catalyst to help hasten the transition from old inefficient systems to new, more sustainable ones.

Related Content

Comments

Deep Dives

RECENT

Editor's Picks

Webinars

Featuring

Lizz Welch & Jennifer Roglà

iDE

May 16 - 12:00 PM EST

Impact Encounters

May 22 - 6:30 PM EST

News & Events

Subscribe to our newsletter to receive updates about new Magazine content and upcoming webinars, deep dives, and events.

Become a Premium Member to access the full library of webinars and deep dives, exclusive membership portal, member directory, message board, and curated live chats.

0 Comments